Automatic logistics system for raw material blending warehouse

System description:

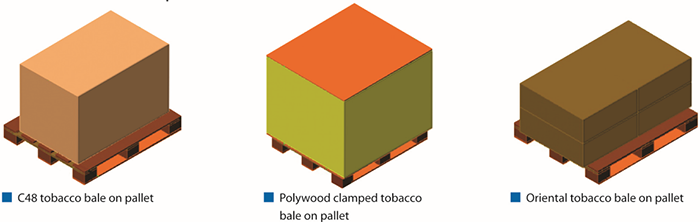

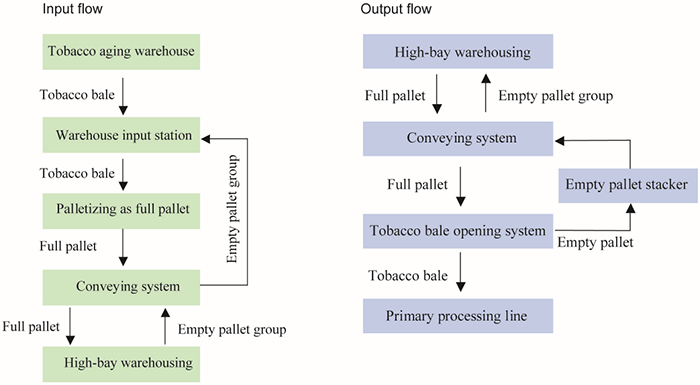

Raw material blending automatic logistics system is set as a bridge between the tobacco aging warehouse and the primary warehouse. It changes traditional extensive producing mode to intensive producing mode with various functions such as accurate blending, batch management, ordinal feeding, even mixing, batch quality control, eliminating mildew tobacco and emergent material supplementary to meet the requirements of flexible blending of primary processing.

System features:

Fit for multiple brands, multiple grades and smaller scale blending requirement.

Improve the production response and support individuation producing,

Single kind of tobacco input, output as per order of batch’s formula blend

Accurate warehouse management, less labor and fewer mistakes.

Working flow:

System composition:

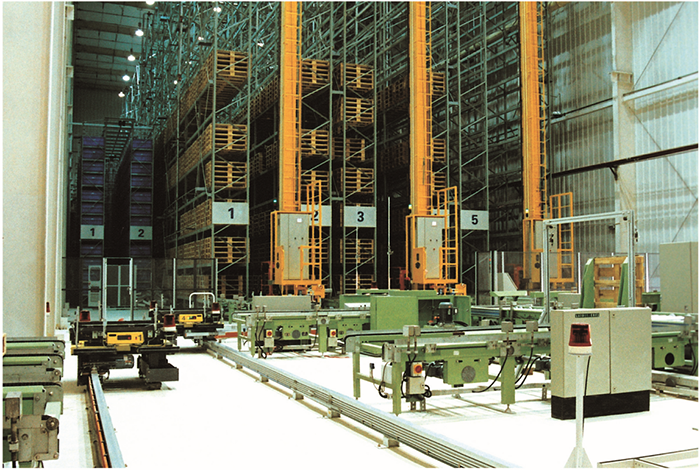

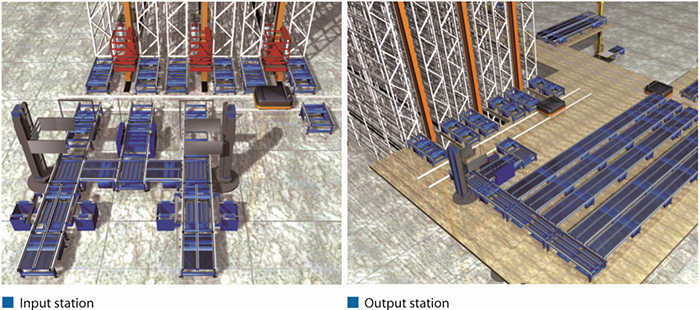

It consists of palletizing system, warehouse input system, automatic storage/retrieval system, warehouse output system, depalletizing system, tobacco bale opening system, electric control and computer management system.