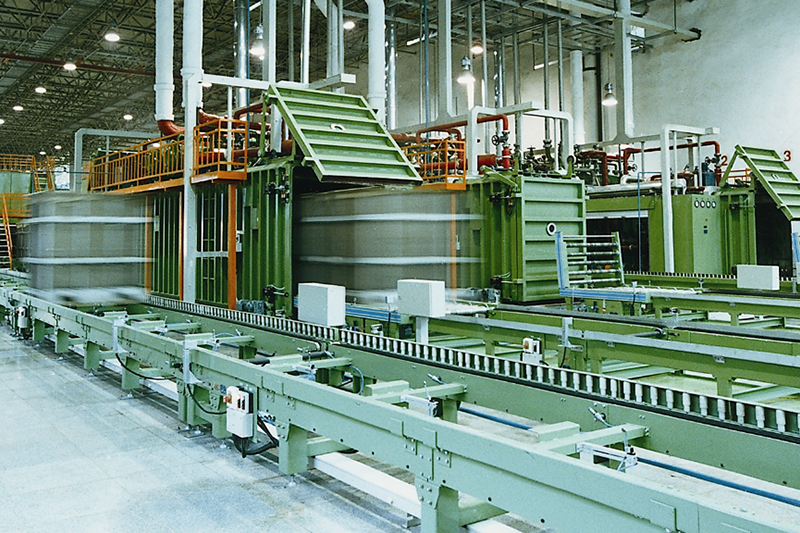

For decades, KSEC has supplied primary processing line with capacity from 300kg/h to 12000kg/h to over 180 cigarette factories in the worldwide. Generally, a complete primary processing line consists of following sections: 1) lamina processing subline, 2) cut-lamina processing subline, 3) stem processing subline, 4) Burley tobacco processing subline, 5) cut-tobacco blending subline. Casing kitchen is required for large scale production scenario.

1) Lamina processing subline

The processing flow of this section usually is: Lamina unpacking (auto or manual) – Slicing – Conditioning (DCC or vacuum conditioning) – Silo (pre-blending and bulking)

2) Cut-lamina processing subline

The processing flow of this section usually is: Discharging from silo – NTRM sorting – Cutting – Expansion – Drying

3) Stem processing subline

The processing flow of this section usually is: Stem unpacking – Stem washing – Expansion & conditioning – Silo – Conditioning – Cutting – Drying

4) Burley tobacco processing section

It set multi casing application before burley toasting and accelerate the casing liquid absorbing. Burley tobacco toaster has function of keeping humidity and drying. It has wide adjustable range of drying temperature and precise moisture control and high automation.

5) Cut-tobacco blending subline

All kinds of cut-lamina, cut-stem, expanded cut-tobacco and reconstitute tobacco will be blended in a certain recipe preset. The blended cut-tobacco will go through metering and flavoring then be stored in a cut-tobacco silo.

Stem Washing Plant

This product is a special plant used for cleaning dirt and direct conditioning...

Read MoreSpiral Stem Conditioning Tunnel Plant

It is used for increasing temperature and moisture content of stem...

Read MoreStem Flattener

It is mainly used to flatten the steamed stems and make them suitable for being cut in tobacco cutter...

Read MoreCarton box opener

It is used to take down the package of a lamina bale. After that, the lamina bale...

Read MoreFork slicer

It is used for slicing lamina bale into several blocks with gap between each in a bin...

Read MoreVacuum conditioning

It is used for continuous and automatic vacuum conditioning of sliced lamina blocks in bin...

Read More