Stacker Crane

Description

Stacker crane is automatic storage and retrieval equipment. It is controlled online by upstream computer and usually works together with other equipment to form a complete automated logistics system for achieving the automatic storage of materials under a variety of complex process environment. KSEC owns lots of patents in stacker crane.

The performance of stacker crane has reached the international standard. It can be widely used in industries such as tobacco, automobile, pharmaceutics, food, home appliances, finance, electricity, aviation, engine, papermaking, machinery manufacturing, national defense, new energy, third-party logistics, etc.

Features

√ Design comply with international standard.

√ Suitable for storage under multiple environments with complex process.

√ Stable operation in high speed and high warehousing frequency.

√ Adopt bus technology and PLC control technology.

√ With good operability and convenient HMI operation interface.

√ Flexible configuration.

√ Infrared communication and wireless communication can be selected.

√ With remote diagnosis function.

√ With complete safety function and multi-level safety control in each direction.

√ Secondary precise positioning function (shelf deflection repositioning) can be selected.

√ Equipped with energy-saving motor, making system more efficient and energy saving.

Supported Pallet

l Pallet (ISD) dimension, mm:1200×1000

l Pallet (non ISD) dimension, mm:1600×1200,1600×2000,1200×1600, 1200×2000

Categories of Unit Storage

Single-depth storage | Double-depth storage |

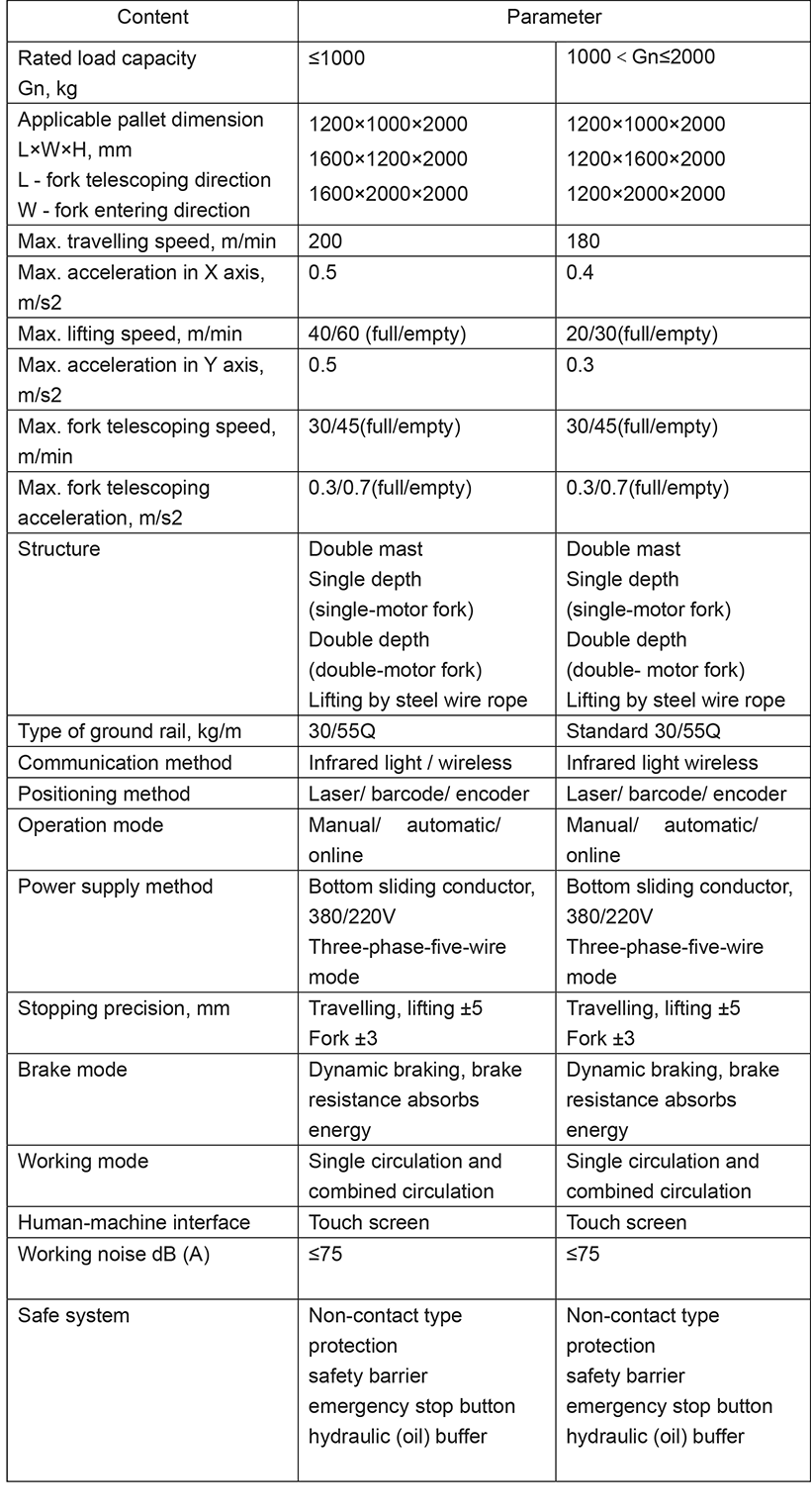

Technical parameter