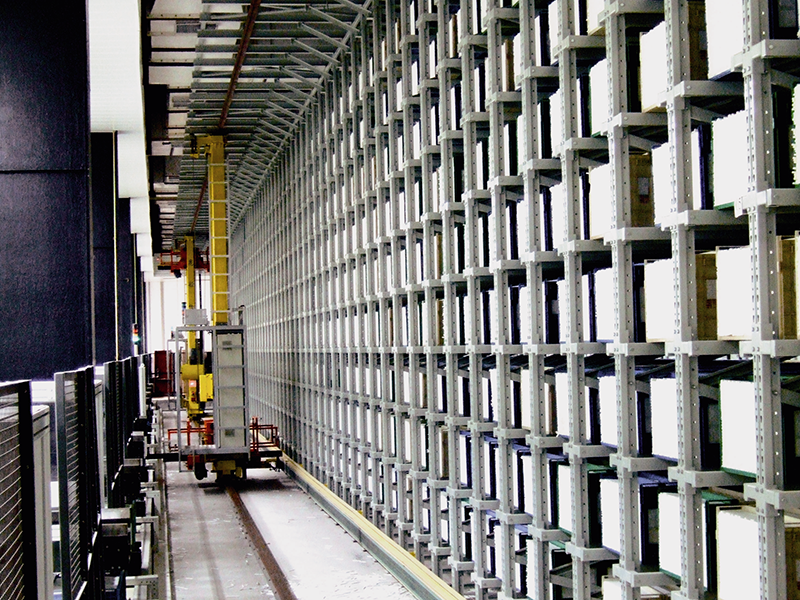

For tobacco industry (filter rod warehouse)

The filters come out from the filter maker and are loaded in the filter tray. Each tray can contain 4200~4500 filter rods. There are totally 558 compartments in the racking system. Each compartment can store 14 trays. The filter rod tray will be automatically transported and stored in the high-bay warehouse for 8 hours for hardness process. When the filter rods are required, the full filter trays are automatically transported to the location of tray unloader. The filter rods are discharged from the tray unloader and sent to the specified inlet of cigarette maker via filter shooter. The empty tray is taken back for filter rod loading or storing in the racking system. Main equipments of the system are: tray loaders, empty & full tray conveyors, tray unloaders, empty tray lifting & shifting device, tray feeding device, stacker crane and racking system.